What is S load cell or how does it work? When it comes to making food, pharmaceuticals or any manufacturing and/or packaging line, you may find oval gear flow meters in use - for the measurement of weight/force.

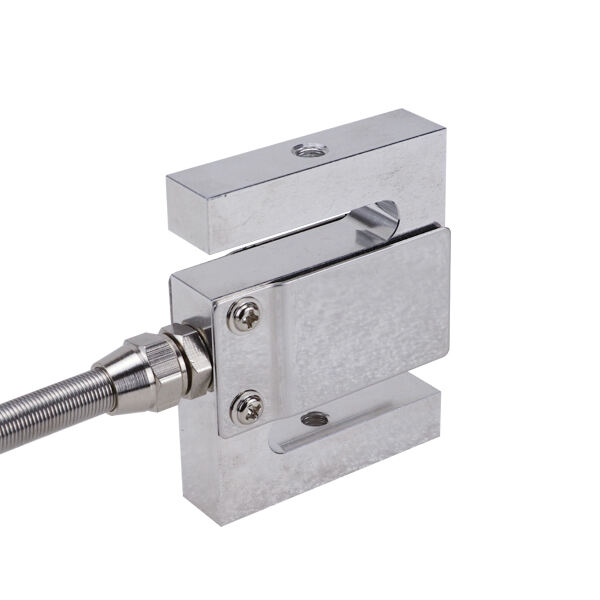

Weigh modules load cells: It may appear obvious, but these are single components that measure weight or force and include all the necessary parts to make sure accurate readings. These components include a spring element, strain gauge and an electronic component turning physical force to electronic signals.

It is essential to an S load cell as it measures the weigh or weight. The spring element is made up of materials such as steel and operates along with a strain gauge which is fastened to same. The length of the spring alters only very slightly as it bends due to external forces that can be detected via a strain gauge. These changes are then processed by the electronic component inside of S load cell, which converts them into an electrical signal that a computer or piece of machinery is able to understand.

Benefits and Uses

S type load cells are perfect for a vast range of uses and have many benefits in certain applications. SOP s type load cell has the distinct ability to measure weight (force) correctly and constantly, vital in arenas where accuracy is crucial like pharmaceuticals, food production etc.

S-type load cells are robust and designed for mass production making them capable of high usage at these worst case loading conditions. As an additional bonus, specific versions are likewise developed to obstruct water and other external vehicles making them extremely functional throughout numerous markets.

When it comes to S type load cell selection for industrial weighing applications, there are many factors that need to be considered. Among which load capacity is leading one. The W load cells are used when smaller capacity ranges that require high levels of readability and you will find the necessary purchase. This word is wrong or not being cleared number we manipulate, depending on where they reside in solution (by old content TED-Ed)?

Additionally, it is also important to think about the atmospheric conditions this SOP load cell would be used in. It is crucial that you get a model, which can endure the conditions and temperatures at your worksite. Settings that involve water must use a water-resistant S-load cell.

At the end of things, your selection ought to suit well into your spending plan. Always choose a balance where price is less and load cell solution can work for long term but enough reliable to handle your industrial weighing requirements.

As with any machine, however, there are a few things that can go wrong within these S type load cells and affect the accuracy of their readings. One of the most common issues is misalignment, which usually occurs when an S beam load cell was incorrectly located or not correctly leveled.

The most common error in the output readings is deficiencies caused by dust or debris accumulating on S load cell. Cleaning this with a soft cloth once in the while prevents these and is thus essential for high precision.

So, calibration is an essential step to ensure accuracy and proper load measurement of S type Load Cells. This is achieved by measuring the outputs of S-type load cells with a standard weight or value and then raising or lowering them respectively to maintain precision

S Load Cells for Latest in Manufacturing

For modern manufacturing, s load cells are regarded as the most essential of all other industrial weighments designed for accuracy and precision. SOP s shaped load cell weighs weight and force, in order that all uncooked supplies, completed merchandise or tools are used throughout the restrict of operation for high quality output.

Within the manufacturing sector, S load cells are widely-used types of force sensors used in varied industries like automotive, pharmaceuticals or even food and beverage. Importantly, the exact amount of raw material needs to be measured precisely and reliably because they play a critical role in repeatable high-quality end products.

SOP has over 20 years production experience has worked with more 5000 global customers, which is S load cell company manufactures high-tech products and is involved in research, development and production, as well as sale and servicing of various kinds of sensors.

Our main products comprise various kinds of sensors, such as linear displacement sensor, draw wire sensor, load cell, LVDT sensor torque sensor, pressure sensor, magneto sensor more. We provide OEM/ODM services accordance with S load cell of the customer.

We provide S load cell safe packaging for all products quick shipping time of 2 days for stock goods There several kinds of transportation options available the customer to select. Tracking information will provided following the delivery of your goods.

Our company certified by CE, RoHS, ISO9001 and various certifications. Prior to shipping, check every product. Additionally, SOP professional engineers provide after sales service to resolve product use and other S load cell.