A rope tension load cell is a special type of device used measure how tight or slack a line, cable or wires are. Because they help maintain safety and ensure that things remain under control, these machines are fundamental to many jobs in various industries. Ropes would be difficult to ensure the proper tightness, which could lead to unsafe situations without these load cells.

Rope tension load cells are important because they gauge the tightness or short lengths as well looser of different types ropes, such elastic gym equipment. This is considerable for many types of structures, such as bridges and buildings. Loose rope, on the other hand, can be quite dangerous and potentially catastrophic if it falls or snaps. Conversely, if it is too loose, this may cause damage to the materials or create more work. Therefore we have to measure it tight enough so that the whole assembly is secured.

How are Rope Tension Load Cells Used in Rock Climbing?... Ropes As safety ropes High walls or cliffs, for example when people go climbing Rope that's too slack will allow climbers to fall. High rear blitz loading or extreme high shoulders position is also dangerous and close to failing. This ensures the ropes are just right and that everyone has a good time, all while feeling comfortable in their respective harnesses.

Rope tension load cells are versatile and used on many different jobs from construction to transportation even NASA uses rope tension sensors! One must measure how many kilograms of weight the rope can carry in these varied functions. This type of perfect money counting avoids accidents and ensures the smooth operation. For example, during construction tugging at ropes with a certain amount of force can prevent load from falling. Transportation requires them so that loads are secure and will not move during transit. These load cells are very important for the safety of operation.

Having high-strength rope tension load cells that are working well will be very important. Secure the work of multiple industries. So you can think a line if really tight when it isn't and that leads to people prematurely un-clipping from the safety of the main lifts this could prove dangerous. Hence, testing is required on regular basis to test these machines for its proper functioning and correct readings.

Last but not least, working with a trustworthy rope tension load cell provider! These engines have to be extremely durable as they should not fail or break down for a long time. They have to be quick and accurate because they should quickly provide the approximate data that is required of them. All of the advantages combine to make these load cells an effective part, which can assure and keep everyone safe.

Customers can select from range of transportation services. We provide secure packaging speedy delivery all stock goods. Tracking information be rope tension load cell after goods are shipped.

We are certified CE, RoHS ISO9001. Our products undergo rigorous rope tension load cell prior delivery. SOP also has engineers who provide after-sales service and solve any issues the product.

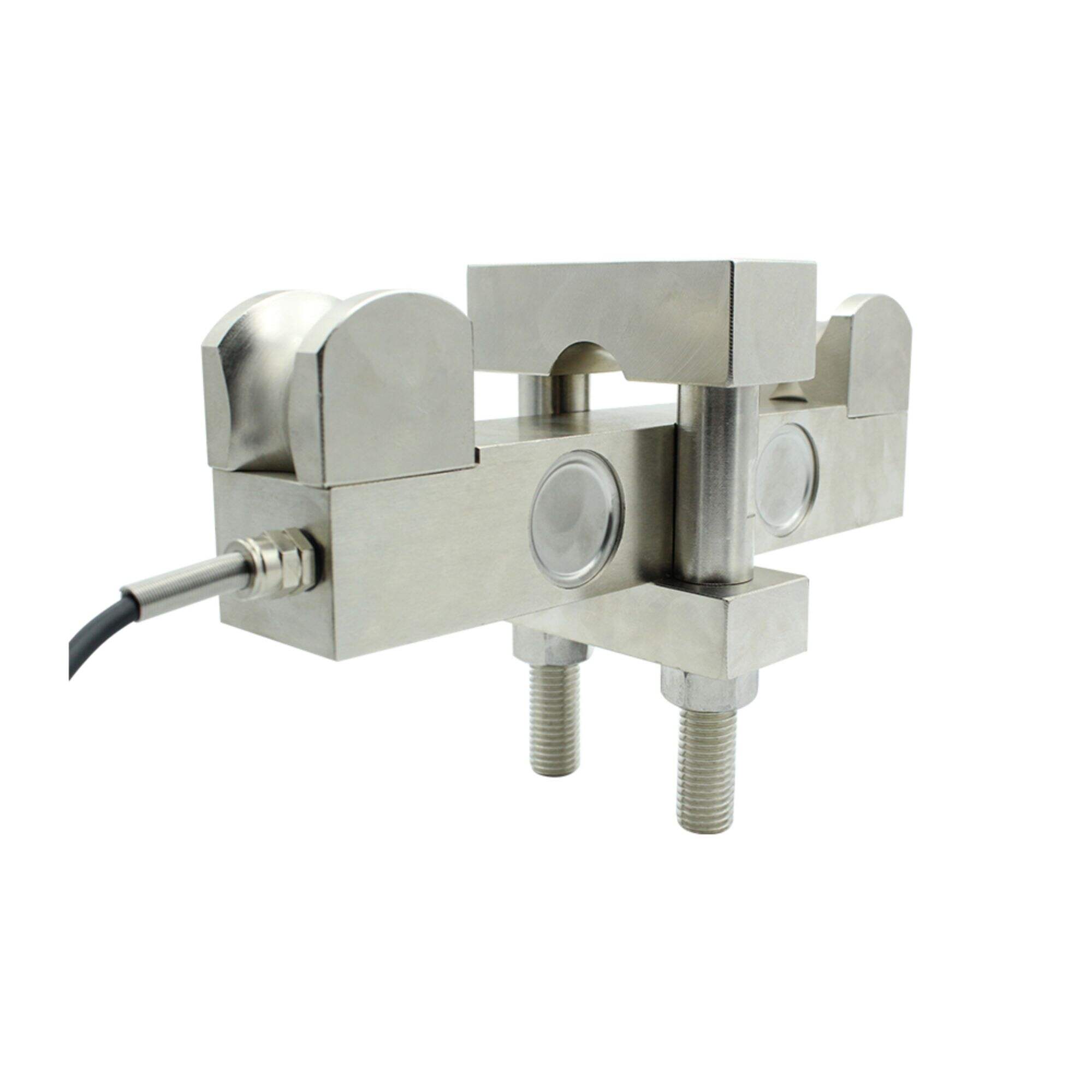

Our main products consist various kinds of sensors, like linear displacement sensors, draw wire sensor, load cell, LVDT torque sensor, magneto sensor, rope tension load cell sensor, many more. We provide OEM/ODM services accordance with the requirements of customer.

SOP has over 20 years production experience and worked over 500 global rope tension load cell. It is professional manufacturer and high-tech enterprise engaged the development, research manufacturing, sales, service of various types of sensors.