pressure sensor factory

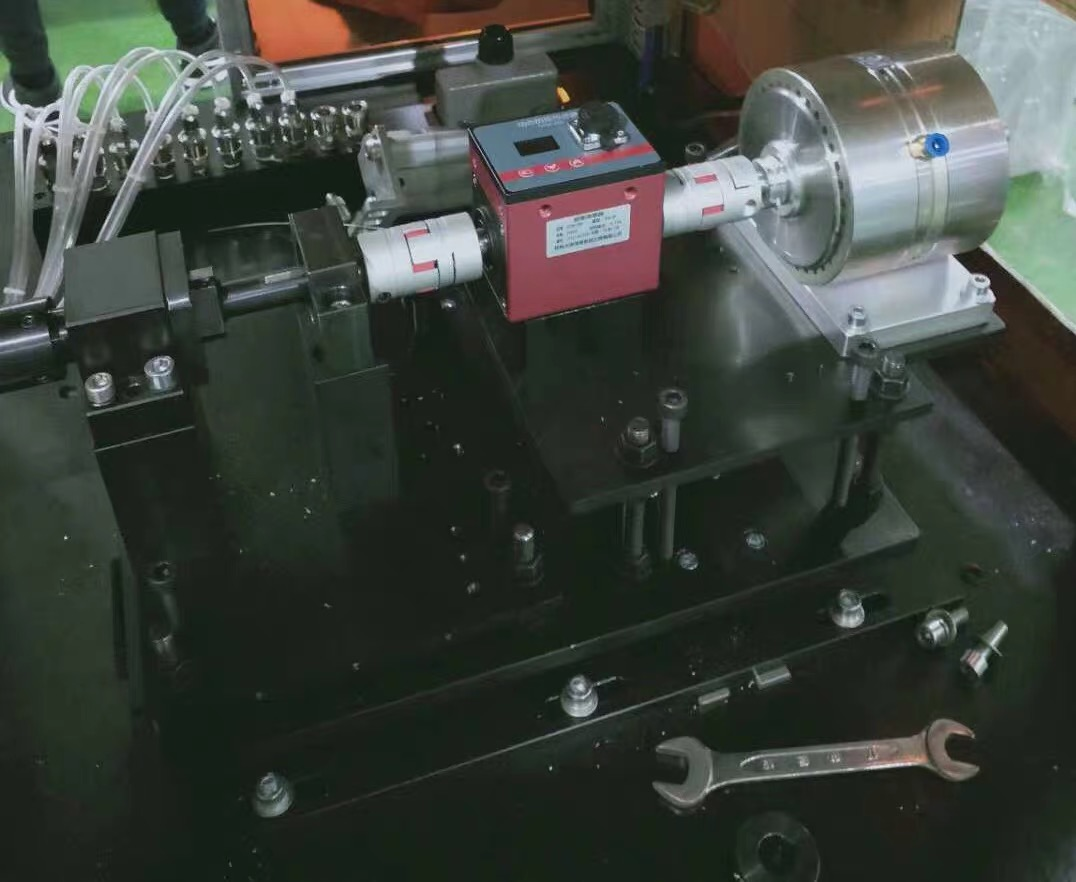

A pressure sensor factory represents a cutting-edge manufacturing facility dedicated to producing high-precision pressure measurement devices. The facility combines advanced automation systems with precise quality control measures to create sensors that meet diverse industrial requirements. These manufacturing plants utilize state-of-the-art equipment and testing facilities to ensure each sensor meets strict performance standards. The factory's main functions include design and development of pressure sensing solutions, manufacturing of various pressure sensor types including piezoresistive, capacitive, and strain gauge sensors, and comprehensive testing and calibration services. The facility's technological features incorporate automated assembly lines, clean room environments for sensitive components, and advanced testing chambers for environmental simulation. These factories typically employ sophisticated quality management systems and maintain international certifications such as ISO 9001. Applications for their products span across multiple industries, including automotive, aerospace, medical devices, industrial automation, and HVAC systems. The factory's capabilities extend to customization of sensors based on specific customer requirements, offering solutions for both standard and specialized applications. Modern pressure sensor factories also emphasize sustainable manufacturing practices and energy efficiency in their operations, while maintaining focus on continuous improvement and innovation in sensor technology.