load cell cost

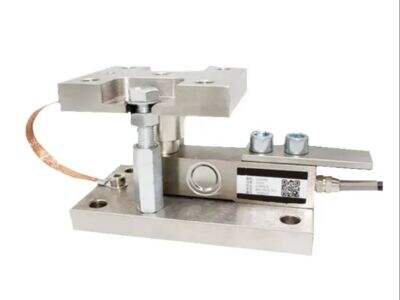

Load cell cost represents a crucial consideration in industrial weighing and measurement applications, encompassing various factors that influence the final price point of these precision instruments. Load cells, essential components in modern weighing systems, convert mechanical force into electrical signals, with costs varying based on capacity, accuracy, and construction quality. The price spectrum ranges from basic strain gauge load cells starting at around $50 to sophisticated digital load cells that can exceed $1,000 per unit. Factors affecting load cell cost include material quality, such as stainless steel versus aluminum construction, environmental protection ratings, and certification requirements. Additionally, the measurement capacity, from a few pounds to several tons, significantly impacts the price. Advanced features like temperature compensation, digital outputs, and hermetic sealing contribute to higher costs but offer enhanced reliability and precision. Manufacturing standards, compliance with international regulations, and warranty coverage also influence the final price. Understanding load cell cost is essential for businesses to make informed decisions that balance budget constraints with performance requirements.