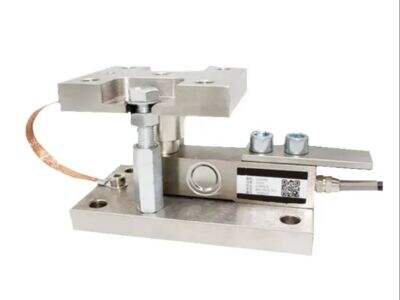

liquid pressure sensor

A liquid pressure sensor is a sophisticated measurement device designed to accurately detect and monitor pressure levels within fluid systems. This essential instrument operates by converting fluid pressure into electrical signals, providing real-time data for various industrial and commercial applications. The sensor employs advanced sensing elements, typically including a pressure-sensitive diaphragm or membrane that responds to changes in liquid pressure. When pressure is applied, the sensor's internal components undergo precise deformation, which is then translated into measurable electrical outputs through piezoelectric or capacitive mechanisms. Modern liquid pressure sensors incorporate temperature compensation and digital signal processing capabilities, ensuring accurate readings across diverse operating conditions. These sensors are engineered to withstand harsh environments, featuring robust construction materials and protective housings that guard against corrosion and mechanical stress. They offer various pressure ranges and output options, making them versatile for different applications, from industrial process control to hydraulic systems monitoring. The technology behind these sensors continues to evolve, with newer models offering enhanced precision, improved reliability, and advanced communication protocols for seamless integration with modern control systems.