Although these have been retired for off-shelf use, hanging load cells were among the first types of a single.

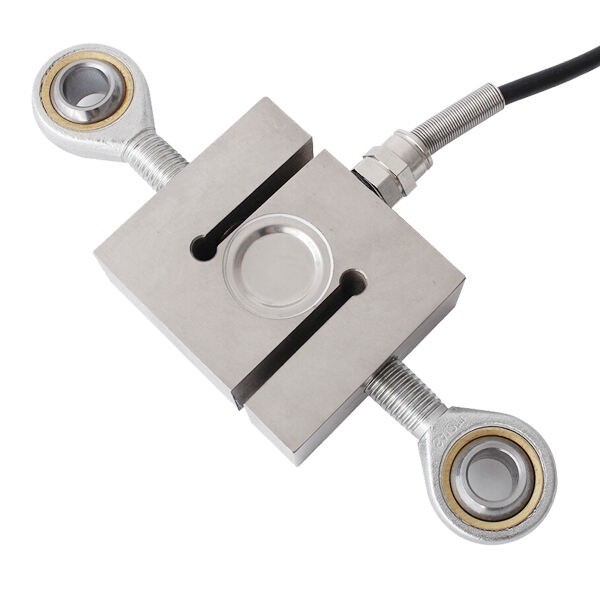

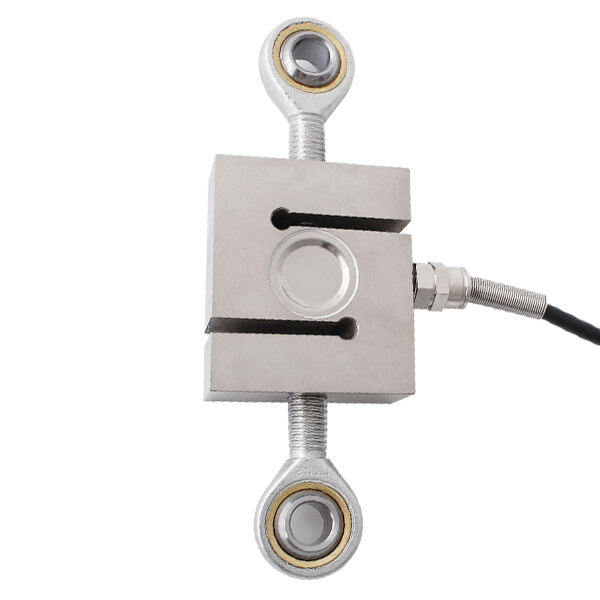

This makes them unique load cells that you need to have in order for any of the different industries and thousands more, allowing every single factory or machine used anywhere else, they load cell are all properly operating with knowing how much weight is anything hanging off these force measuring sensors. They SOP looked like small metal boxes, but each of them had a pair of long metal hooks on their bottom edges. They constructed of steel to shoulder the wait.

The hanging type load cells operate by measuring the tension force that is applied to a hook at one end of the sensor. This SOP force is then converted into an electrical signal which exits the Load Cell after providing a reading on display unit in terms of weight. This type of scale extracts or measures liquified and solid materials for industrial applications in industries like transportation, construction and manufacturing to determine the exact weight load that heavy machines are carrying.

Now it is all featured on hanging load cell with technology to make it more accurate and efficient.

In order to have the a load cell best possible accuracy and efficiency in your hanging load cell technology, you must strictly follow all specified install instructions and weight capacity limitations. Improper installation can result in noticeably different readings that could jeopardize both your safety and budget.

Calibration is the SOP process by which you configure a load cell to measure loads accurately. In order to load cell sensor provide accurate weight measurements, you must calibrate regularly. Product quality is compromised (which may be as a result of readings failing) Material being handled incorrectly Proper storing of the hanging load cells is also important for getting their correct readings. Proper lubricant, debris and wear would help to make the cap locking equipment last longer while less time spend on down-time.

You need to be quite careful in term of the weight readings for which, it is important that you pick up on inside with right and recommended hanging load cell options. This load cell amplifier can result in inaccurate readings and potential safety issues occurs when load cells are wrongly used or overloaded.

Customers are able choose from a wide range transportation options. We provide secure packaging fast shipping for stock goods. Once the package been delivered is Hanging load cell, you will receive tracker details.

We are certified by CE, RoHS ISO9001. Before shipment, examine each product. SOP also Hanging load cell engineers provide after-sales service solve any issues the product.

We provide a broad range products, including linear Hanging load cell sensors drawn wire sensors, load cells, LVDT sensors well as torque Senors, pressure sensors, magneto sensors, many more. We offer OEM/ODM support depending on the needs of client.

SOP is a high-tech manufacturer has over 20 years of Hanging load cell production and worked with more than 5000 customers around world. It is a well-established company engaged research, development and production of different types of sensors.