buy linear transducer

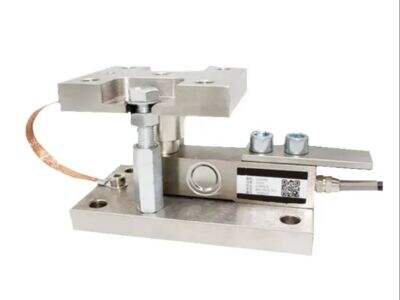

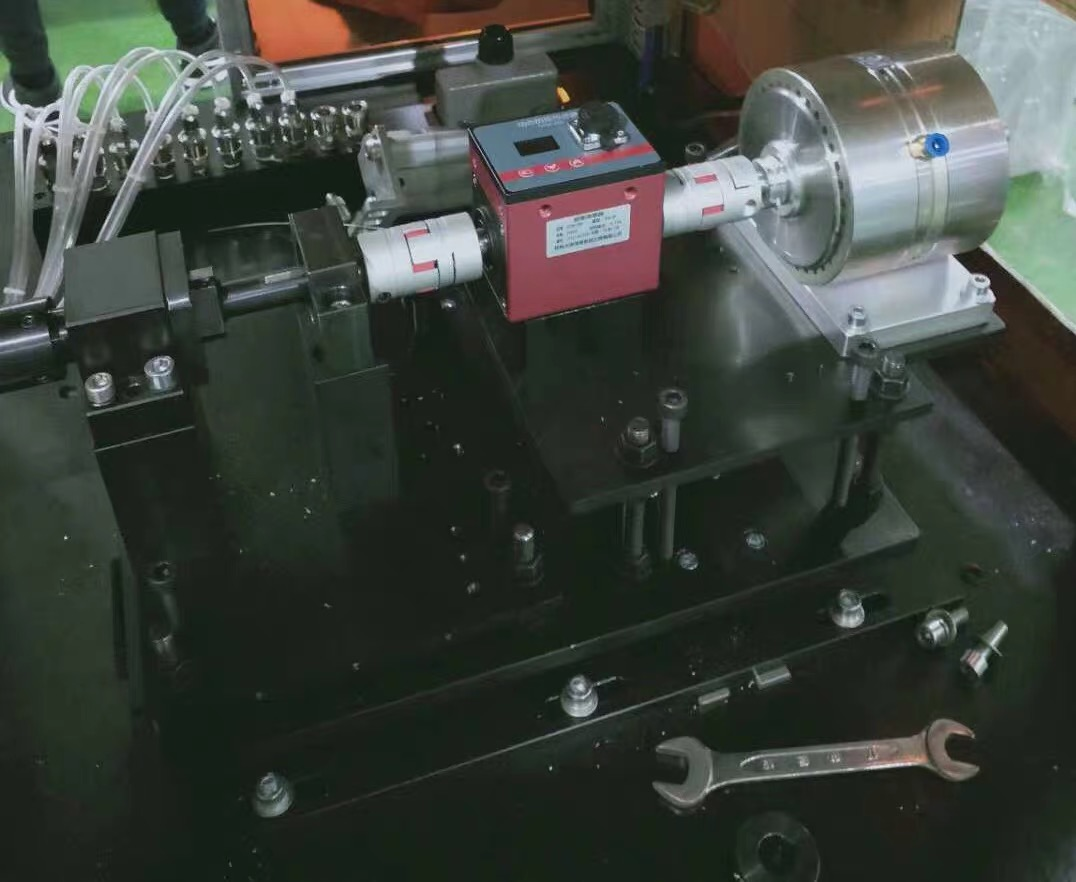

A linear transducer is a sophisticated measurement device that converts mechanical motion into electrical signals with exceptional precision and reliability. This advanced instrument operates on the principle of linear displacement, providing accurate measurements across various industrial and medical applications. The device features state-of-the-art sensing elements that maintain consistent performance throughout their operational lifetime, ensuring dependable results in demanding environments. Modern linear transducers incorporate digital signal processing capabilities, enabling real-time data acquisition and analysis. They offer multiple interface options, including analog, digital, and wireless connectivity, making them versatile tools for diverse measurement needs. These transducers are engineered with robust housing materials that protect sensitive internal components from environmental factors, ensuring long-term durability. The measurement range typically spans from microscopic movements to several meters, with resolution capabilities down to micrometers. Advanced models feature temperature compensation mechanisms, maintaining accuracy across varying environmental conditions. The integration capabilities of these devices make them ideal for automated systems, quality control processes, and precision manufacturing applications.