Button Type Load Cells are used to measure applied force or weight in these instances and they perform an essential function. These devices, often little more than a small button with the smallest of holes in its center that is where pressure is applied to you (not much dissimilar from an electric circuit board), are very sophisticated electronic components. These elements change in electrical resistance when a nick is placed on them, giving the cappotent capability of measuring exactly how much force or weight you are applying to something.

One of the key characteristics that make button type load cells so efficient is their design. This configuration is ideal for tight spaces as it can be more compact and easier to mount in place. What is more, these load cells are highly accurate and can determine even a tiny force that makes them invaluable in branches of activity requiring no rough movements - medical equipment/lab research etc. But their sturdiness allows for other, more demanding uses as well like in manufacturing plants and industrial settings.

Button type load cells have a wide range of applications, from measuring the force required to press the key on a computer keyboard until evaluating muscle strength during physical therapy. These flexible gizmos fit everywhere, from hand-operated devices to heavy commercial equipment. Button Type Load Cells: Besides, for the safety and dependability of their products industries like aerospace and automotive depend on button type load cells.

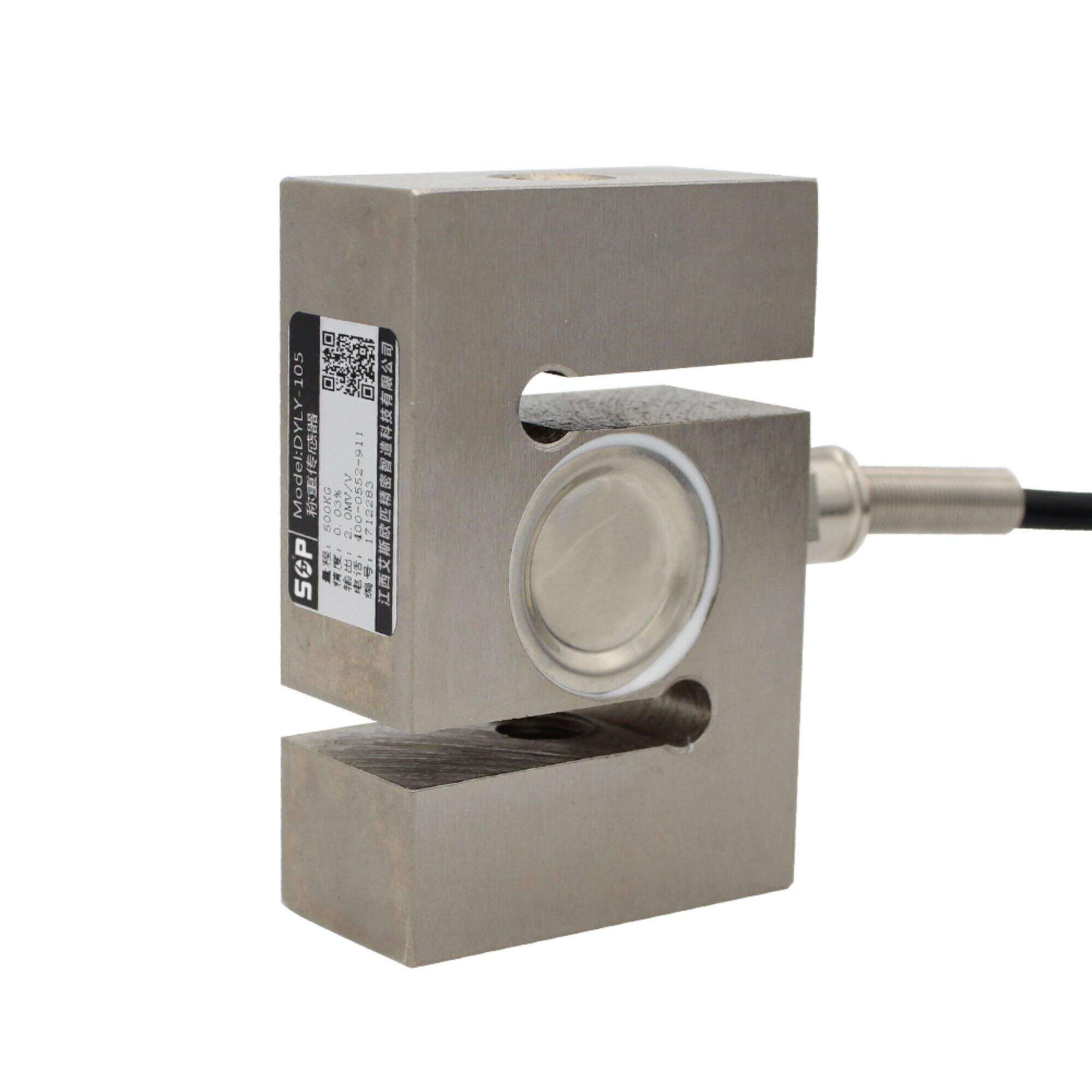

Button type load cells have several integral pieces that work together to make the unit function. The metallic body of the load cell, usually made from stainless steel or aluminum, glasses in side to protect sensitive electronic components. This body is used as a base from where we measure the applied force.

Strain GaugeA strain gauge is a device used to measure the tensile and compressive forces that work across an object due to a change in its shape. A strain gauge is bonded to a metal diaphragm inside the load cell, and that resistance changes when force deforms the diaphragm. The internal electronics inside the load cell then, interprets and calculates this change in resistance.

Finally, the load cell built-in electronics for signal amplifying and processing of strain gauge output. Located on a small circuit board inside the load cell, these electronics are electrified by a tiny battery or can also be connected to an additional power source.

There are several factors that need to be taken into account when selecting button type load cell. The first and often overlying force is the maximum scale weight a load cell can measure. Load cells can be found in sizes that cover a large spectrum, measuring forces of grams to many tonnes; therefore selecting the model which suits your conditions is vital.

Beyond that, you need to consider what level of accuracy the load cell must provide. Different applications require different levels of precision. Some need highly accurate results, while others can get by with less precise calculations. Selecting a Load Cell: The balance of precision and cost

The load cell will be used on is also another important thing you have to consider. The selection of load cells for such environments should be based on the intended use - capable devices to work well under high temperatures, humid conditions or with exposure to corrosive substances.

Finally, but not least are the physical dimension of your load cell. As the area available is confined, a choice for right load cell size which goes into that space needs to be made.

Button type load cells, without doubts being of one the most reliable types may still suffer from issues originating in problems with drift, noise and zero shift.

Drift is observed in the readings over time, irrespective of force being applied. The load cell can be recalibrated or a temperature-compensated version, engineered to counterbalance any changes that occur due to altering temperatures.

In both cases, electrical noise-occasioned by either internal or external to the load cell-may be suppressed by shielding which also justifies mandatory selection of a low-noise model.

Recalibration or use of load cells designed to withstand mechanical strain can prevent zero shift over time.

We provide button type load cell safe packaging for all products quick shipping time of 2 days for stock goods There several kinds of transportation options available the customer to select. Tracking information will provided following the delivery of your goods.

We are accredited by CE, RoHS ISO9001. We ensure every item undergoes a rigorous inspection prior button type load cell. SOP also has engineers can offer after-sales services solve any problems with the product.

We provide a broad range products, including linear button type load cell sensors drawn wire sensors, load cells, LVDT sensors well as torque Senors, pressure sensors, magneto sensors, many more. We offer OEM/ODM support depending on the needs of client.

SOP has over 20 years production experience and worked over 500 global button type load cell. It is professional manufacturer and high-tech enterprise engaged the development, research manufacturing, sales, service of various types of sensors.