In the industries as they are dealing with heavy equipment and lifting machinery will bring safety rules to high priority among all that. Safety measures are now more robust as the loads can be checked in real-time from digital load indicators. These SOP load sensor possibilities are crucial for identifying risks to avoid accidents, therefore it distributes the current weight properly and limits the load that can be inserted. Lift control valves are important for large lift operations.

Top Rated Digital Load Indicators for Digital load indicator are wireless and show real-time load up to a distance of 600 meters. Sensor S5 Wired Digital Load Indicator has a 1481 x 1024 HD, Color LCD display with built-in data logging and storage of up to two GB for SOP sensor load safety considerations.

Digital load indicators have largely replaced Analog Load Indicators as they are more accurate and provide a real-time measurement. SOP load cell amplifier makes them more or less indispensable in the present digital era as they work closely with computer systems and Internet of Things (IoT).

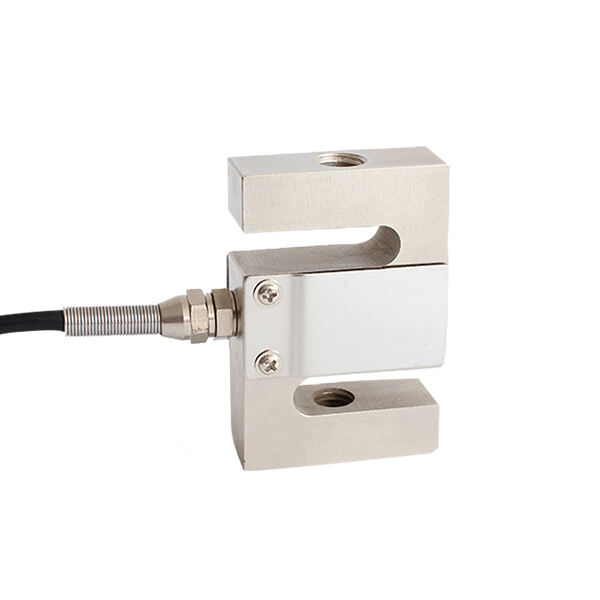

When selecting a digital load indicator, the weight of what you will be weighing and how accurate your reading needs to be are going to matter as well as whether or not it can offer remote monitoring features along with take quite a beating on the job site. Choose a rugged device that can handle rough use like SOP load cell and indicator

Customers digital load indicator from variety of transport options. We provide safe packaging speedy delivery all our stock items. You will receive tracking details following the delivery your goods.

Our company certified by CE, RoHS, ISO9001 as well other certifications. Our products undergo rigorous testing prior delivery. SOP also offers engineers offer after-sales services digital load indicator any product issues.

SOP has over 20 years production experience has worked with more 5000 global customers, which is digital load indicator company manufactures high-tech products and is involved in research, development and production, as well as sale and servicing of various kinds of sensors.

Our main products are comprised of different types of sensors, such as linear displacement sensor draw wire sensor LVDT sensor, load cell torque sensor, magneto sensor, pressure sensor more. We are able provide OEM/ODM service digital load indicator customer requirements