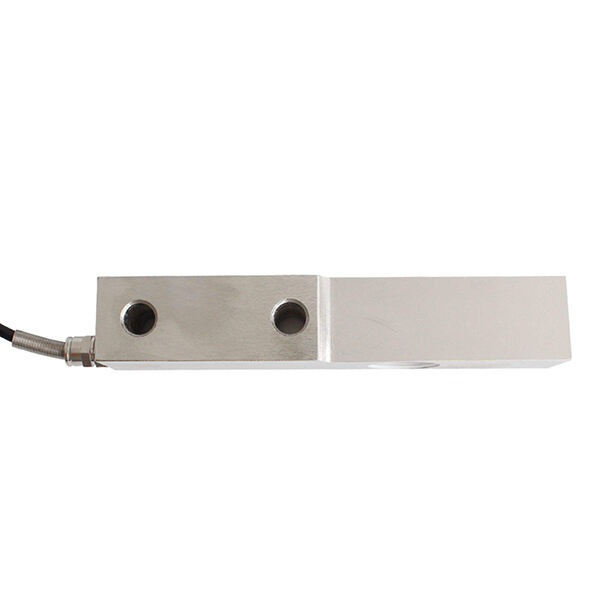

In industrial weighing applications, a Compression type load cell is employed as unique measurement device to gauge the weight or force of an object. This SOP compression load cell works by pushing a material such as metal and observing its deformation/strain to store the output. Then, the deformation is translated into an electrical signal that can be measured by a control system or display.

The chart shows multitude of industrial applications by each major configurations in Compression load cells. These include: Button Type Load Cells - These load cells are designed specifically to weigh small forces or loads, ensuring high precision measurement. Variety of Donut Load Cell TypeLoadcells donut (compression tension load cells) are used in applications where space is restricted, they provide an extremely solid constructing combined with very high accuracy beneath a pressure system influenced top. Canister Type Load Cells: These load cells are of cannister type (look like a body or cannister) which is very suitable for measuring high forces and weights with utmost precision. Application :It is useful in a wide range of industries such as automotive / aerospace/ construction or food process.

This article will help you make sure that the load cell solutions selected are right for your particular requirements. Capacity - Verifying the load cell can accommodate the maximum force or weight it is intended to measure. Essentially, this SOP tension and compression load cell indicates a load cell needs to be exactly enough so that the force or weight it is measuring satisfies some level. Environment Suitability: that the station or base is working fine at asking for conditions (example, temperature sensor)

Some benefits of a compression load cell that these organizations experience, both quickly on their site and later in the rest of industrial operations are. Accurate weighing, force measure. Durability and Damage Immunity They work well in continuous use situations (durability) However, compression load cells have downsides too like that even best operating supposedly needs on a regular basis calibration and maintenance.

The Choice on an appropriate compression type load cell for a specific industrial application is largely based on factors of how much quantity and range of force or weight to measure, which level accuracy need be maintained (or achieved), Finally but not at all the least under what kind of environmental conditions this classic linear sensor will perform. Although expert advice is certainly recommended before selecting a particular load cell for the purpose. To wrap up I will say that compression type load cells are used to measure the ex cat weigth/force in industry. Every person must have the most thorough knowledge of how to work along with species and purposes etc. so that one can configure wisely while choosing their appropriate compression load cell for consistent precision reading forever. This SOP tension compression load cell is why selecting the right compression load cell is important in order to ensure efficiency and productivity throughout manufacturing.

We provide secure safe packaging every item and speedy compression type load cell of 2 days delivery stock goods There are numerous types transportation options available customer to choose. The tracking information will be sent to you once the product is shipped.

Our company certified by CE, RoHS, ISO9001 and various certifications. Prior to shipping, check every product. Additionally, SOP professional engineers provide after sales service to resolve product use and other compression type load cell.

We provide a broad range of products include linear displacement sensors drawn wire sensors, LVDT sensors, load cells torque sensors, pressure sensors, compression type load cell sensors, more. We offer OEM/ODM support per the specifications of the customer.

SOP is a leading compression type load cell has over 20 years' manufacturing experience has worked with over 500 clients around world. SOP is a reputable firm is involved in the development, research production of various kinds of sensors.