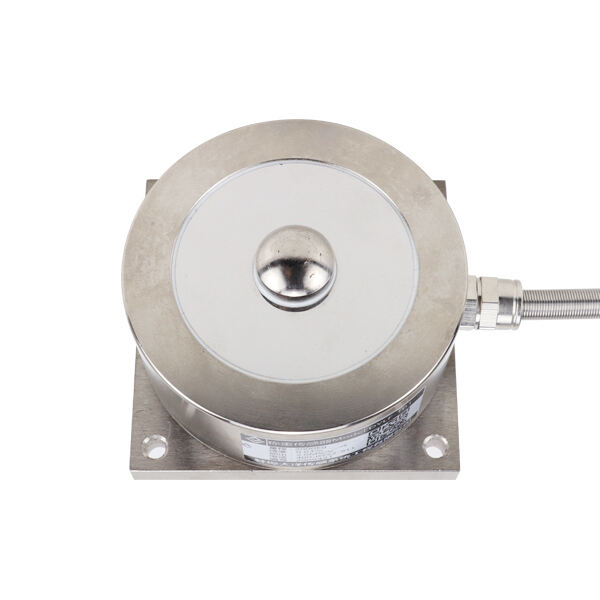

Weighing force transducer: Weighing-scale that tells us how heavy something is in weight. Normally it is made of strong metal and capable even detect almost negligible differences in weight. Take it all together, put something moving on top of it and squeeze just a bit the little heavy thing so they can perceive HOW MUCH! This measurement it then translate into a figure we determine the mass of object. This is critical as it allows us to determine precise weights of items.

There are a number of things that one has to keep in mind when choosing the right kind of load cell for SOP load cell. The very first thing you have to figure out is: What kind of a weight range are we looking at that the load cell has to measure? A durable load cell will also be a must if you are trying to weigh something that is very heavy as well. You need to purchase the one that can handle your maximum weight. setBackgroundColor. setTextColor(yellow)

The accuracy of a load cell is another critical determinant. Sure, some load cells measure weight better than others. Since load cells are for precise work, say you use it on an experiment or even make a recipe in the kitchen must be ordered right next to a high precision force transducer according with specifications shown above. In this way, you will be able to trust your measurements are accurate and correct.

Weighing load cells are so precise that any less-than-the-best highest possible level of accuracy will fail. An error in measurement, no matter how small SOP weigh cells is cause the severe trouble each and every time this occurs literally. If you are a baker let's say the cakes. and if your ingredients measure wrongly so does this mean that there will be no good cake bake or some other recipes for that matter. There is why baking everything accurately becomes so important.

Essentially, the end goal is making sure that your load cells continue to effectively function and provide good readings (via induced resistance) when required. This means making sure that check if they have any damage such as dents or scratches and also keep SOP a load cell away from dirt and debris especially hire soiled their house can be. It is crucial to keep these in great shape so that they provide accurate and precise readings.

With advances in past times, and of today's technological capabilities advancements to the load cell-how pressure sensor could be improved upon or what new ideas are out there-are quite possible. For example, many load cells now function using digital technology in order to improve their accuracy level when taking weight measurements. That way, we have extremely precise weight measurements that are consistent.

Our company been Weighing load cell by CE, RoHS, ISO9001 as well other certifications. Before shipping, we inspect each product. SOP also engineers can provide after-sales service solve any issues with the product.

Customers are able choose from a wide range transportation options. We provide secure packaging fast shipping for stock goods. Once the package been delivered is Weighing load cell, you will receive tracker details.

Our main products are comprised different types of sensors, such Weighing load cell displacement sensor drawing wire sensor LVDT sensor, load cell torsion sensor, magneto sensor, pressure sensor, etc. We provide OEM/ODM services depending on the need's client.

SOP has over 20 years production experience worked with over 5000 global clients, is a reputable company manufactures high-tech products is involved in the research, Weighing load cell manufacturing, sales and servicing of various kinds of sensors.